In the realm of industrial manufacturing, precision and durability are paramount. Rolls PCD Notching Tools have emerged as a game-changer, offering unparalleled performance for notching rolls across various industries. At Halnn, we specialize in providing top-tier PCD (Polycrystalline Diamond) notching tools designed to meet the rigorous demands of modern manufacturing. This article delves into the benefits, applications, and reasons why Halnn’s Rolls PCD Notching Tools are the optimal choice for your notching needs.

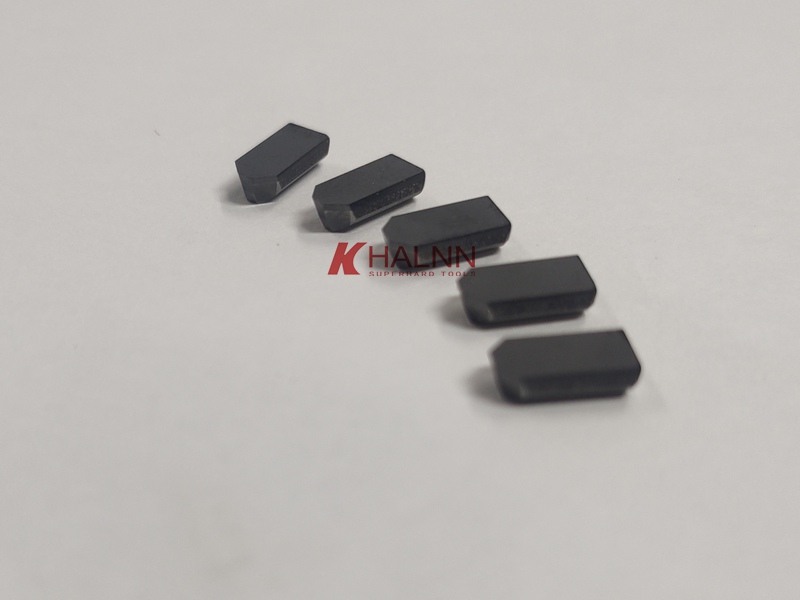

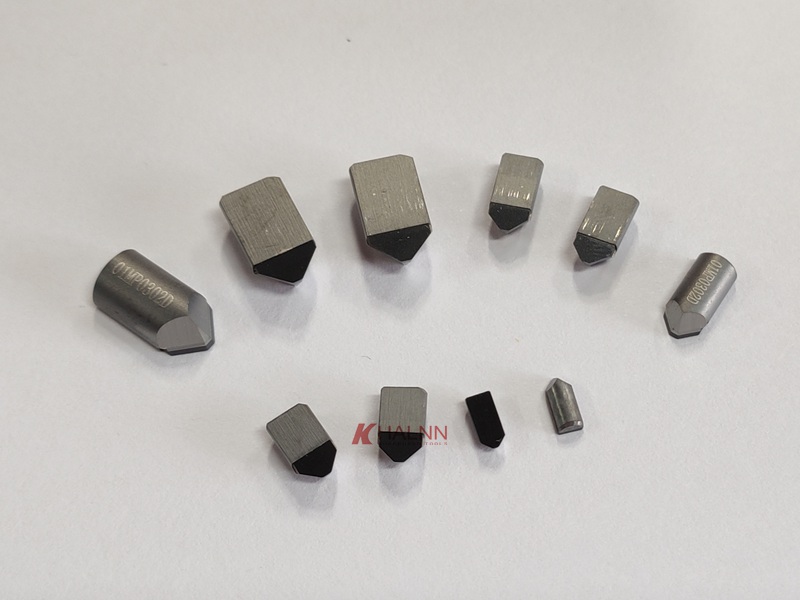

Rolls PCD Notching Tools are specialized cutting instruments crafted from Polycrystalline Diamond (PCD), a material renowned for its exceptional hardness and wear resistance. These tools are specifically engineered for notching rolls, which are essential components in machinery used for shaping, cutting, and finishing various materials.

Polycrystalline Diamond (PCD) is synthesized by sintering diamond particles under high pressure and temperature, resulting in a material that surpasses traditional cutting materials like carbide and high-speed steel (HSS). PCD’s superior hardness ensures that Rolls PCD Notching Tools maintain their sharpness and effectiveness even under the most demanding conditions, providing consistent performance and extended tool life.

At Halnn, we pride ourselves on delivering Rolls PCD Notching Tools that offer exceptional performance and value. Here are some key benefits of choosing our PCD notching tools:

Halnn’s Rolls PCD Notching Tools are built to last. The inherent properties of PCD ensure that our tools resist wear and tear, significantly extending their lifespan compared to conventional tools. This durability reduces the frequency of tool replacements, leading to lower operational costs and minimal downtime.

Precision is critical in notching rolls to ensure the quality and functionality of the final product. Our PCD notching tools provide superior accuracy, enabling fine and consistent cuts. This precision minimizes material waste and enhances the overall efficiency of your manufacturing process.

While PCD tools may have a higher initial investment, their extended lifespan and reduced maintenance needs make them a cost-effective choice in the long run. Halnn’s Rolls PCD Notching Tools offer excellent value by delivering high performance without frequent replacements.

The robust nature of PCD means that our notching tools require less frequent maintenance. This reduction in maintenance efforts translates to increased productivity and less interruption in your manufacturing operations.

Halnn’s Rolls PCD Notching Tools are versatile and can be utilized across a wide range of industries where precision and durability are essential.

In automotive manufacturing, precise notching of rolls is crucial for producing high-quality components such as gears, shafts, and other intricate parts. Our PCD notching tools ensure that these components meet strict quality standards, enhancing the performance and reliability of automotive products.

The aerospace industry demands the highest levels of precision and reliability. Rolls PCD Notching Tools from Halnn are ideal for notching rolls used in the fabrication of aerospace components, ensuring consistency and excellence in every cut.

Metalworking requires tools that can handle tough materials while maintaining precision. Our PCD notching tools excel in notching rolls used for shaping and cutting hardened steels and other robust alloys, providing efficient and accurate results.

Notching rolls are also pivotal in the paper and textile industries for cutting and shaping materials. Halnn’s PCD notching tools deliver the precision needed to produce high-quality products with minimal waste.

Halnn offers a diverse range of PCD notching tools tailored to meet specific manufacturing needs. Here’s an overview of our product offerings:

Our standard PCD notching tools are designed for common applications across various industries. These tools offer a balanced combination of performance, durability, and cost-effectiveness, making them suitable for everyday use.

Understanding that each manufacturing process has unique requirements, Halnn provides customizable Rolls PCD Notching Tools. Whether you need a specific geometry, specialized coatings, or unique specifications, our team can tailor the tools to meet your exact needs.

For niche applications or particularly challenging materials, Halnn offers specialized PCD notching tools. These tools are engineered to deliver enhanced performance characteristics, ensuring optimal results even in the most demanding scenarios.

Selecting the appropriate PCD notching tool is crucial for achieving the desired outcomes in your manufacturing process. Here’s a guide to help you make the right choice:

Assess the specific material you’re working with, the precision needed, and the production volume. Rolls PCD Notching Tools from Halnn are ideal for projects that demand extended tool life and high accuracy.

Examine the cutting speed, durability, and tool geometry to ensure that the Rolls PCD Notching Tool you select aligns with your project’s requirements.

For complex or highly specialized applications, seek expert guidance from Halnn. Our team can help you select or customize the right PCD notching tool to meet your unique project demands.

Proper maintenance is essential to maximize the performance and lifespan of your Rolls PCD Notching Tools. Here are some maintenance tips:

After each use, clean the tools to remove any material buildup. This practice prevents corrosion and maintains the tool’s cutting efficiency.

Store your PCD notching tools in a dry, controlled environment to protect them from moisture and contaminants that could cause damage.

Regularly inspect your tools for signs of wear or damage. Early detection of issues can prevent unexpected downtime and ensure continuous operation.

Understanding how Rolls PCD Notching Tools compare to tools made from other materials can help you make an informed decision.

While carbide tools are more affordable initially, PCD tools offer superior wear resistance and a longer tool life. This makes PCD tools more cost-effective over time, especially in high-volume production environments.

HSS tools are less expensive but lack the durability and precision of PCD tools. Rolls PCD Notching Tools from Halnn provide better longevity and cutting quality, making them a superior choice for demanding applications.

The field of PCD notching technology is continually evolving, with ongoing advancements enhancing tool performance and capabilities.

Recent developments in PCD synthesis and tool manufacturing have led to even more durable and precise notching tools. Innovations in coating technologies and tool geometry further enhance the performance of Rolls PCD Notching Tools.

The future of PCD notching tools lies in increased customization and the integration of smart technologies. These trends aim to provide even greater precision and adaptability to meet the evolving needs of various industries.

At Halnn, we are dedicated to staying at the forefront of PCD technology. Our investment in research and development ensures that our Rolls PCD Notching Tools continue to set industry standards for quality and performance.

A leading automotive manufacturer implemented Halnn’s Rolls PCD Notching Tools in their production line. The result was a 30% increase in production efficiency and a significant reduction in tool-related downtime, showcasing the effectiveness of our PCD tools in high-demand environments.

An aerospace component supplier utilized our specialized PCD notching tools for cutting composite materials. The precision and durability of our tools ensured consistent quality and met the stringent standards required in the aerospace industry.

A metal fabrication company adopted Halnn’s Rolls PCD Notching Tools for their hardened steel projects. The tools’ superior wear resistance and accuracy led to improved product quality and lower operational costs.

The main benefits include exceptional durability, unmatched precision, cost-effectiveness, and reduced maintenance requirements due to the superior properties of PCD.

Consider the material you’re working with, the required precision, and the production volume. Halnn offers both standard and customizable solutions to meet your specific needs.

With proper care, these tools require minimal maintenance. Regular cleaning and appropriate storage will help maintain their performance and extend their lifespan.

Yes, Halnn specializes in offering custom PCD notching tools tailored to your specific application and project requirements.

While PCD tools have a higher initial cost, their extended tool life and reduced maintenance make them more cost-effective in the long run compared to carbide or HSS tools.

Choosing Halnn means partnering with a leader in the cutting tool industry. Here’s why Halnn stands out:

Custom Solutions: We tailor our Rolls PCD Notching Tools to meet your unique manufacturing requirements.

Expert Support: Our team of experts provides personalized guidance and exceptional after-sales support.

Commitment to Quality: We adhere to the highest standards of quality and precision in every tool we produce.

Innovative Technologies: Continuous investment in research and development ensures that our tools incorporate the latest advancements in PCD technology.

Halnn Rolls PCD Notching Tools offer an unmatched combination of precision, durability, and cost-effectiveness, making them the ideal solution for notching rolls in various industries. By choosing Halnn, you gain access to cutting-edge technology, expert support, and tools that enhance your manufacturing efficiency and product quality.

For more information about our Rolls PCD Notching Tools or to request a custom solution tailored to your specific needs, contact Halnn today.

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.