In industries that rely on high-speed and precision machining, the choice of cutting tools plays a vital role in ensuring efficiency and productivity. One of the most crucial tools used in rolls machining is HSS rolls inserts—designed specifically for cutting high-speed steel (HSS) rolls. As an expert provider of cutting solutions, Halnn offers premium HSS rolls inserts that combine durability, precision, and versatility, making them ideal for challenging industrial applications. In this article, we will delve into what HSS rolls inserts are, their key features, advantages, and why Halnn is the best choice for your rolls machining needs.

HSS rolls inserts are precision cutting tools engineered for machining rolls made from high-speed steel (HSS). These inserts are critical in applications where maintaining high cutting speeds and exceptional surface finishes are necessary. Unlike conventional cutting tools, HSS rolls inserts are optimized to handle the hardness and toughness of HSS rolls, ensuring long tool life and minimal wear, even in demanding conditions.

By maintaining sharp edges and high durability, Halnn’s HSS rolls inserts offer consistent performance in the most challenging machining environments, making them the preferred choice for industries like steel production, automotive manufacturing, and heavy machinery.

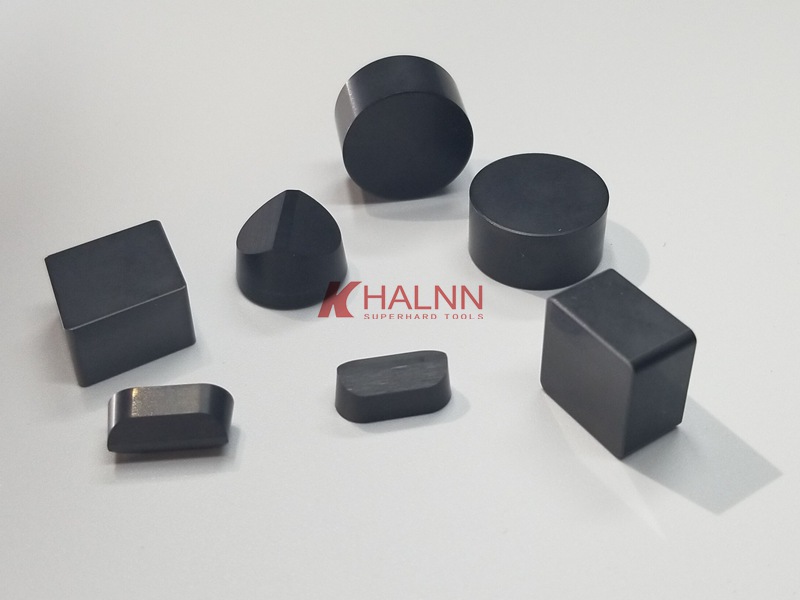

At Halnn, we design our HSS rolls inserts with the highest level of precision and innovation, ensuring that they meet the specific needs of modern industrial machining. Some of the standout features of our inserts include:

Precision Machining Capability: Halnn’s HSS rolls inserts are engineered for high accuracy, delivering smooth and consistent cutting results across various materials.

Durability and Wear Resistance: The high-quality materials used in Halnn’s inserts ensure exceptional wear resistance, enabling the tools to maintain sharpness even during prolonged use.

Superior Heat Resistance: During high-speed machining, Halnn’s HSS rolls inserts can withstand extreme temperatures, reducing the likelihood of tool deformation or loss of performance.

Custom Solutions: We understand that each machining application is unique, which is why Halnn offers customizable inserts tailored to your specific machining needs.

HSS rolls inserts offer several advantages over other types of cutting tools, particularly in applications involving the machining of hardened rolls. Some of the key benefits of Halnn’s HSS rolls inserts include:

1. Longevity: The toughness and durability of HSS rolls inserts ensure that they last longer than many conventional tools, reducing the need for frequent replacements.

2. Cost-Effectiveness: Though HSS inserts may have a higher upfront cost, their long lifespan and resistance to wear result in significant cost savings over time.

3. High Cutting Speeds: Designed for high-speed applications, these inserts can maintain precision at elevated cutting speeds, maximizing productivity while minimizing downtime.

4. Versatility: HSS rolls inserts are suitable for both continuous and interrupted cutting, making them versatile across different industries and machining conditions.

5. Superior Surface Finish: The precise cutting edges of Halnn’s HSS rolls inserts ensure superior surface finishes, which are essential in industries that require high-precision components.

HSS rolls inserts are essential tools across various industries that deal with tough, wear-resistant materials. Some common applications of Halnn’s HSS rolls inserts include:

Steel Industry: Halnn’s HSS rolls inserts are widely used in the steel industry for machining HSS rolls in rolling mills. The inserts are perfect for handling the hardness and toughness of steel rolls, delivering precision cuts and extending tool life.

Automotive Manufacturing: The automotive industry relies on high-precision components, and HSS rolls inserts from Halnn provide the durability and accuracy needed to machine these parts efficiently.

Forging and Heavy Machinery: HSS rolls inserts excel in machining forged steel rolls and other heavy machinery components, where strength and wear resistance are critical.

Whether it’s hot or cold rolling mill applications, Halnn’s HSS rolls inserts are designed to handle the toughest materials with ease, providing exceptional results across multiple industrial sectors.

When it comes to precision machining, Halnn is a name you can trust. We have years of experience in developing cutting tools that meet the most demanding industrial requirements. Here are a few reasons why Halnn is the best choice for HSS rolls inserts:

Industry Expertise: With a wealth of experience in cutting tool technology, Halnn has established itself as a leader in the field. Our team of experts continuously innovates to provide the best solutions for rolls machining.

Innovative Technology: Halnn’s HSS rolls inserts are crafted using cutting-edge materials and design processes, ensuring that our products stay ahead of the competition in terms of performance and durability.

Tailored Solutions: We offer customized HSS rolls inserts to meet the unique needs of our clients. Whether it’s a specialized cutting geometry or a custom grade, Halnn provides tailor-made solutions that maximize performance.

Comprehensive Support: Halnn offers complete customer support, from helping you select the right tool for your needs to providing after-sales services that ensure your machining operations run smoothly.

Selecting the right HSS rolls inserts for your machining operation requires careful consideration of several factors. Here’s what to keep in mind:

1. Material Hardness: The hardness of the rolls you are machining is a critical factor in determining the right tool. Halnn offers a wide range of HSS rolls inserts that are designed to handle different material hardness levels, ensuring optimal performance.

2. Cutting Speed: High cutting speeds require inserts that can maintain performance without excessive wear. Halnn’s HSS rolls inserts are designed to work efficiently at elevated speeds, delivering superior cutting results.

3. Tool Geometry: The geometry of the tool—such as rake angle, relief angle, and insert shape—plays a crucial role in achieving the desired surface finish and tool life. Our team at Halnn provides expert guidance to help you select the ideal tool geometry for your specific application.

4. Interrupted vs. Continuous Cutting: Different machining applications involve either continuous or interrupted cutting. Halnn’s HSS rolls inserts are versatile enough to handle both types of cutting, ensuring consistent performance in all conditions.

Proper maintenance of your HSS rolls inserts can significantly extend their lifespan and improve their performance. Here are some best practices:

Optimize Cutting Parameters: Using the correct cutting speed, feed rate, and depth of cut is essential to minimize wear and maximize productivity. Halnn provides detailed guidelines for each type of insert.

Regular Inspection: Periodic inspection of your HSS rolls inserts helps identify wear early, allowing for timely replacements or reconditioning to avoid unexpected downtime.

Coolant Usage: Proper coolant application can help manage heat generation, reduce tool wear, and improve surface finish quality.

HSS rolls inserts are cutting tools specifically designed for machining high-speed steel (HSS) rolls. These inserts are engineered to handle the hardness and toughness of HSS materials, providing precision and durability in various industrial applications.

HSS rolls inserts are widely used in industries like steel production, automotive manufacturing, forging, and heavy machinery. These industries require precision machining of tough materials, and HSS rolls inserts are ideal for these demanding applications.

HSS rolls inserts offer several benefits, including:

Longevity and resistance to wear

Superior cutting performance at high speeds

Excellent toughness for both continuous and interrupted cutting

Ability to maintain sharpness and precision in challenging conditions

Unlike carbide or ceramic tools, HSS rolls inserts are optimized for machining high-speed steel rolls, offering better toughness and shock resistance. They are particularly suited for interrupted cutting operations, which may cause other tools to chip or wear out faster.

HSS rolls inserts are designed specifically for machining high-speed steel rolls. However, they can also be used on other tough materials like hardened steels, cast irons, and certain alloys, depending on the application.

Yes, HSS rolls inserts are built to withstand high-speed machining operations. They are designed to retain their sharpness and cutting ability even at elevated speeds, making them ideal for industries that require fast and efficient machining.

HSS rolls inserts are versatile and can handle both continuous and interrupted cutting operations. Their toughness and wear resistance make them particularly effective in interrupted cuts, where other tools may chip or break.

To choose the right HSS rolls inserts, consider factors like the hardness of the rolls, the cutting speed, the type of cutting (continuous or interrupted), and the specific requirements of your machining operation. It’s also important to consult with tool experts like Halnn for tailored solutions.

To extend the lifespan of HSS rolls inserts, you should:

Follow recommended cutting parameters, including speed and feed rates

Regularly inspect inserts for wear and replace them as necessary

Use appropriate coolants to reduce heat buildup during machining

Halnn is a trusted provider of high-quality HSS rolls inserts, offering precision tools that are designed for longevity, performance, and efficiency. Our expertise and custom solutions ensure that you get the best cutting tools for your specific needs.

For industries that require high precision and durability in rolls machining, Halnn’s HSS rolls inserts are the ideal solution. With our focus on innovation, quality, and customer support, Halnn provides cutting tools that ensure superior performance in a variety of industrial applications. Whether you're machining HSS rolls or other challenging materials, our HSS rolls inserts deliver reliable results that improve productivity and reduce costs.

For more information about Halnn’s HSS rolls inserts, or to inquire about customized solutions, contact Halnn today.

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.