It is well known that rolls are known as the mother of rolled materials, and as the main working component of continuous plastic deformation of metal on the rolling mill, it seriously restricts the operation rate and output of the rolling mill. Then do you know that with the progress of metallurgical technology and the evolution of steel rolling equipment, the quality and manufacturing process of the roll have been continuously improved, and the most intuitive performance should be that the hardness, wear resistance, strength toughness are getting higher and higher.

At present, cast iron rolls, cast steel rolls, high speed steel rolls, Tungsten carbide rolls( ring) are widely used in the market.

Then the more the roll application, the more obvious the problems exposed by the roll processing,such as:

First, Because the diameter of the roll is too large, the processing time of a single piece is long, leading to serious wear of the tool before it goes to the end, resulting in the workpiece having to be reworked and redone, which seriously affects the processing efficiency;

Secondly, there are casting flaw such as scab, air hole and white hard spot in the roll of high hardness casting, so it often leads to the tools broken of the tool and even the phenomenon of "breaking edge".

In addition, the material hardness of large roll parts such as high-hardness metallurgical rolls, high-speed steel rolls and Tungsten carbide rolls is very high, and their own conditions lead to processing difficulties.

Finally, with the addition of spray welding, repair welding, laser cladding and other materials, the surface hardness of roll parts is higher and the cutting is more difficult.

In view of these problems in the roll machining process, Halnn has specially developed a complete set of tool plans, including turning, milling, grooving, notching, marking, etc. in addition to providing standard CBN/PCD tools, Halnn also provides a series of products such as turning Arbor, milling Arbor, support block, CVD engraving tools, etc. Halnn has successfully provided complete sets of roll tools for hundreds of steel mills.

In the field of rolls, why can Halnn be so tough? The reason is that Halnn, as the forerunner of the localization of superhard tools in China, has its own superhard tool research and development center based on the National key Laboratory of Superhard Materials and Henan University of Science and Technology. From the beginning, it has focused on the research of brittle and hard materials and difficult-to-cut materials, using CBN tools and high-grade diamond in the research direction of turning instead of grinding, ultra-high hardness and heavy-duty cutting, and high-speed machining. Difficult-to-cut material cutting and other subdivision areas have unique advantages!

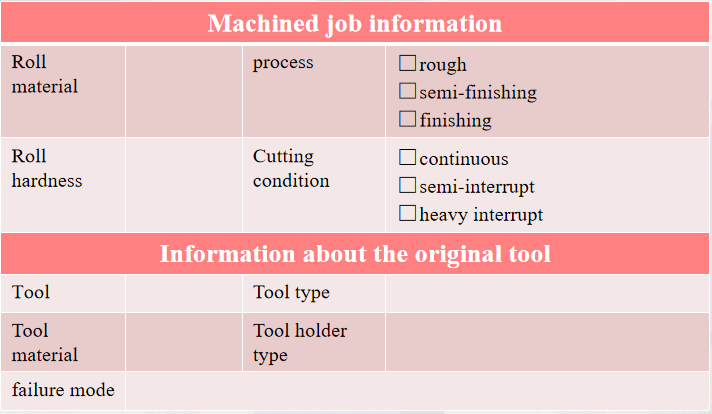

In addition, if some customers do not know how to choose roll tools, they can provide the following table information. Halnn will arrange professional tool sales engineers to provide you with tools selection and technical services. one-on-one to help you quickly solve the roll difficult machining problem.

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.