why Halnn CBN tools work so well in the roll field?

After in-depth research and analysis,We will discuss it from use and manufacture.

First of all, Halnn tools have excellent impact resistance, especially in the field of roll roughing. After many machining tests, we find that the tool will not break in the machining process.

Secondly, Halnn CBN tools have excellent wear resistance and can replace carbide tools and ceramic inserts at low cost. This makes Halnn CBN tools a cost-effective choice in roll processing, providing customers with an excellent experience.

Next, from the manufacturing point of view, Halnn CBN tools have the following three characteristics:

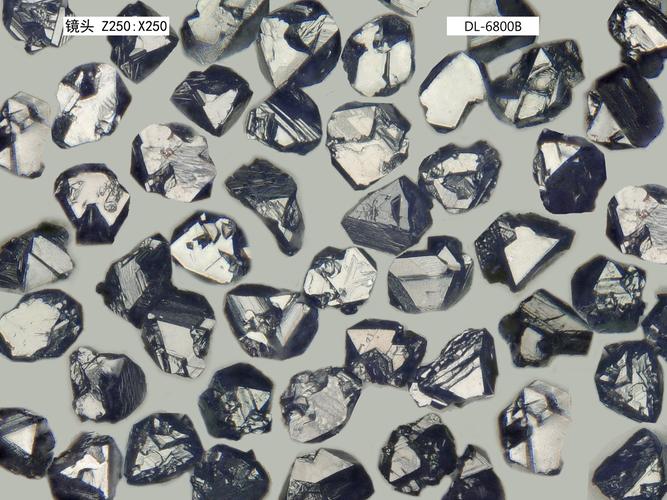

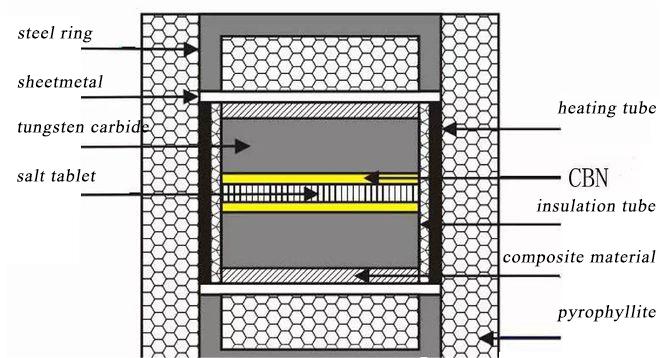

First of all, the performance of the CBN tool mainly depends on the embryoid performance of the tool, unlike carbide inserts that require complex grooves and coatings. Therefore, Halnn has sufficient cost in material selection, selects raw materials with high purity and high purification rate, and adopts reliable and standardized embryo body synthesis process, which directly determines the high quality embryo material of CBN tools.

Secondly, the grinding process and accuracy directly affect the micro-performance of cutting, which is well known in the industry. Therefore, Halnn uses high-end peripheral grinder equipment, higher quality and durability of CBN tools than ordinary grinders, and provides customers with more excellent cutting performance.

Third, Halnn has established a strict inspection system to ensure product quality. All factory tools are subject to comprehensive inspection, in addition to dimensional accuracy and surface quality inspection, but also microscopic inspection of the electron microscope. These strict inspection methods ensure the high quality of Halnn CBN tools.

After passing the inspection, Halnn tools will use four layers of strict packaging to minimize the impact of vibration and bumps in the transportation process on the products. In addition, the "landing re-inspection" system is also adopted in the packaging process, that is, if the tools are slightly scratched by human errors in the process of packing, they will be re-inspected, and only qualified tools will be loaded into the box.

To sum up, the excellent use effect of Halnn tools in the roll field stems from its excellent impact resistance and wear resistance. In the manufacturing process, Halnn pays attention to the selection of materials, the use of high-end equipment and the establishment of a strict inspection system to ensure the stability of product quality, which together promote Halnn tools to achieve excellent results in the roll field.

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.