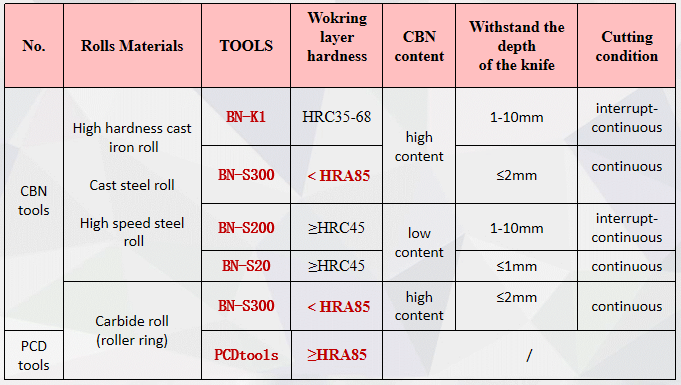

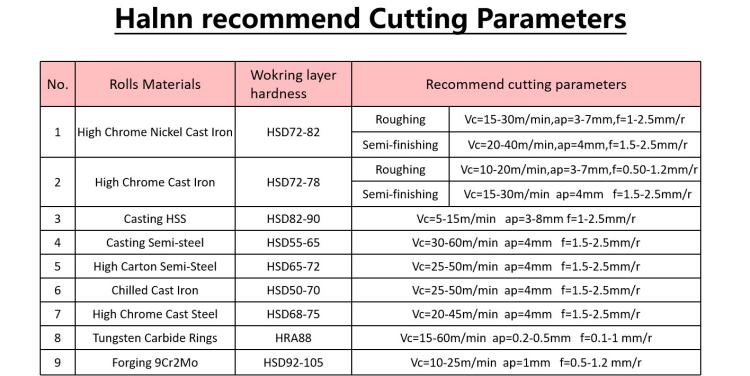

First is the grade choose, For high hardness cast iron and steel rolls, and high speed steel rolls, CBN tools BN-K1, BN-S20, , BN-S300, HLCBN grade are recommend.

And most kinds of use tools are the standard CBN turning inserts, carbide notching and marking tools.

For the Tungsten carbide rolls, we recommend the CBN tools and PCD tools. If the hardness Below HRA 88, we will use CBN tools. If hardness above HRA88, the PCD tools is recommend. And process this material rolls, we most use standard CBN and PCD tools, notching Tools, and PCD marking tools.

CBN tools are mainly most the CNC process, which can be used for rolls turning, milling, grooving, even the repair and so on. And most use the Solid CBN inserts and full face inserts, like the hot use modle SNGN, RNGN and RCGX.

At the same time, according to customer requirement, the CBN inserts with positioning groove or pit can be make to achieve more reliable position. which effectively meet CNC machining.

As mentioned earlier, Halnn not only the CBN tools work well, the PCD tools also excellent performance for machining carbide rolls. And most use CBN tools and PCD tools have full face RNGN,RCGX, RPGN inserts,PCD and CBN Notching tools, and PCD marking tools.

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.