Halnn offers two choices of CBN inserts and PCD inserts for different types of rolls. CBN inserts, including BN-K1, BN-S20, BN-S200, BN-S300 and HLCBN, are recommended for high hardness cast iron rolls, cast steel rolls and high speed steel rolls. For tungsten carbide rolls, halnn recommends the use of PCD inserts, including full face PCD inserts RCGX models, PCD notching inserts and diamond engraving tools. The successful application of halnn tools in Finish turning forged steel cold rolls, Turning the high boron steel rolls Groove and high speed steel roll machining, showing the high efficiency and high quality performance of halnn tools. Through these cases, the audience can be more at ease to choose halnn CBN/PCD tools for roll machining.

I’m going to share Halnn inserts’ application cases in roll field:

Firstly, it is "Finishing turning cold rolls of forged steel ". of which hardness is HRC60. We recommend the customer to replace carbide insert with our CBN inserts BN-S20, than the processing efficiency increased by five times.

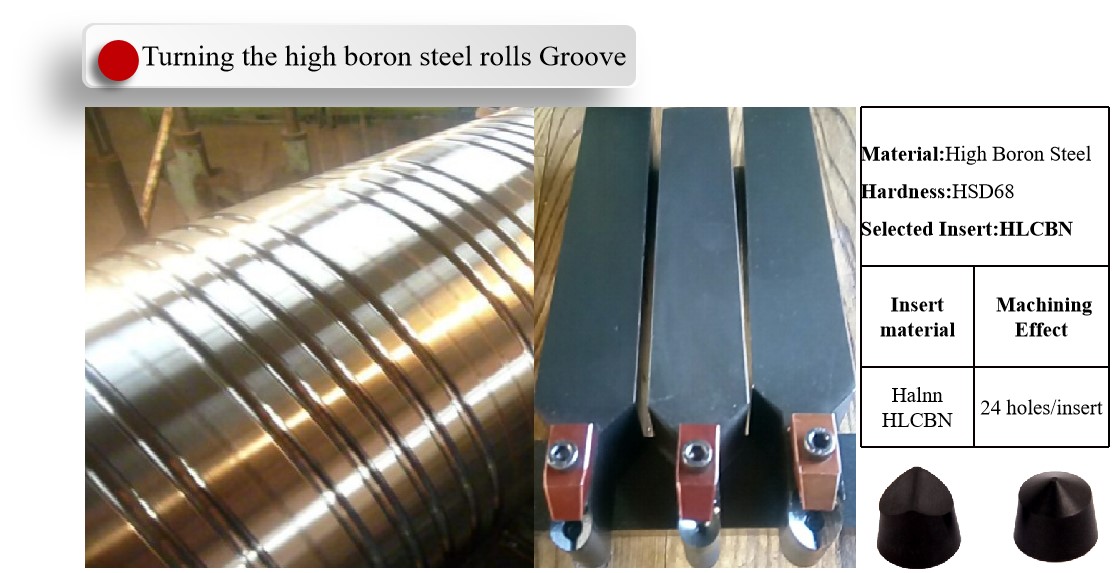

Secondly, it is " high boron steel rolls groove processing", the hardness of the roll is HSD68. Customers tried Halnn's CBN inserts HLCBN series inserts, each insert can process 24 slots, get both higher machinning accuracy and longer tool life.

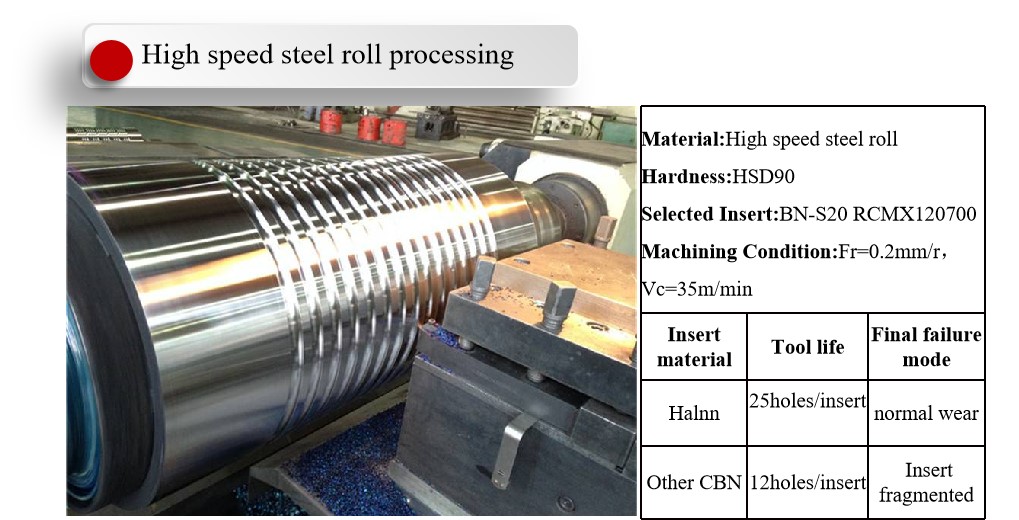

Finally, it is “high-speed steel roll processing”, the hardness of the roll is HSD90. Customers tried Halnn's BN-S20 solid CBN inserts, the tool life is twice as long as a other certain CBN insert.

By these successful machining cases, you can see the excellent performance of Halnn’s CBN insert product. If there is any demand, Welcome to contact us at any time .

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.