In the realm of precision machining, the choice of tool holders plays a critical role in ensuring accuracy, efficiency, and overall performance. One such essential component is the PSC End Mill Holder, known for its reliability and versatility. This article delves into the intricacies of PSC End Mill Holders, highlighting their benefits, features, applications, and why Halnn stands out as a premier provider of these precision tools.

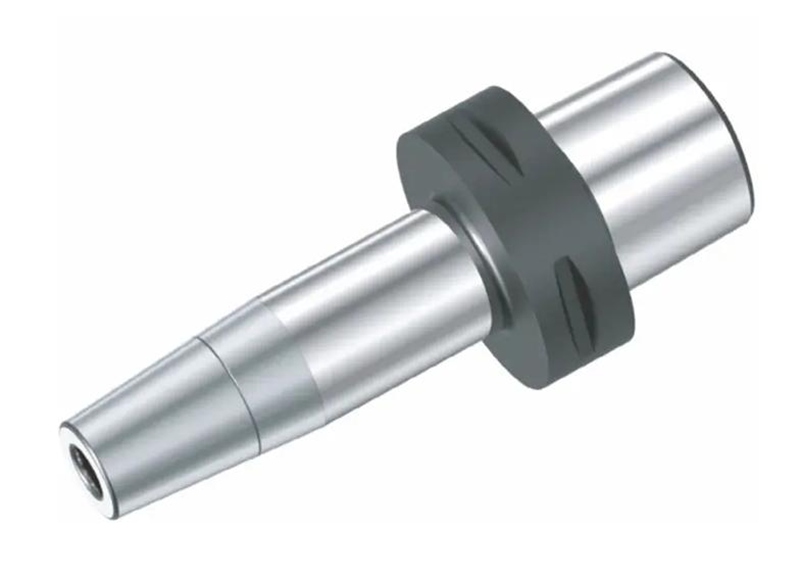

A PSC (Polygon Shank Coupling) End Mill Holder is a type of tool holder designed to securely hold end mills, ensuring optimal stability and precision during machining processes. The PSC system is known for its polygonal shape, which provides a high degree of accuracy and repeatability. These holders are essential for various machining operations, including milling, drilling, and reaming.

PSC End Mill Holders consist of several key components:

Shank: The polygonal shank design ensures a secure fit and minimizes tool runout.

Collet: Holds the end mill in place, providing a firm grip to prevent slippage.

Nut: Tightens the collet around the end mill, ensuring stability.

Compared to other types of end mill holders, PSC holders offer superior clamping force and precision, making them ideal for high-precision machining applications.

PSC End Mill Holders are designed to minimize tool runout, ensuring that the cutting tool remains in the exact position throughout the machining process. This precision results in better surface finishes and tighter tolerances.

The polygonal shank design of PSC holders provides superior clamping force, reducing the risk of tool slippage. This stability is crucial for maintaining consistent performance, especially in high-speed machining operations.

PSC End Mill Holders are compatible with a wide range of machines and tools, making them versatile for various machining tasks. They can be used for milling, drilling, and reaming operations, among others.

By providing a secure and stable grip, PSC holders reduce the wear and tear on cutting tools. This extends the life of the tools, reducing the need for frequent replacements and lowering overall tooling costs.

Halnn is renowned for its precision tool holders, and its PSC End Mill Holders are no exception. Here are some standout features:

Halnn's PSC End Mill Holders are made from high-quality materials that ensure durability and long-lasting performance. The superior build quality ensures that these holders can withstand the rigors of high-precision machining.

Halnn incorporates advanced engineering principles in the design of its PSC End Mill Holders. The polygonal shank design, combined with precision manufacturing processes, ensures exceptional performance and reliability.

Halnn's PSC End Mill Holders are designed to be compatible with a wide range of machining centers and cutting tools. This versatility makes them a valuable addition to any machine shop.

Halnn offers customization options to meet the specific needs of its customers. Whether you require a particular size or design feature, Halnn can provide tailored solutions to enhance your machining operations.

PSC End Mill Holders find applications across various industries due to their precision and versatility. Here are some key industries where they are extensively used:

In the aerospace sector, precision and reliability are paramount. PSC End Mill Holders are used for machining critical components such as turbine blades, engine parts, and structural components.

The automotive industry relies on PSC End Mill Holders for manufacturing engine parts, transmission components, and other precision parts that require high accuracy and repeatability.

Medical device manufacturers use PSC End Mill Holders for producing surgical instruments, implants, and other medical components that demand exceptional precision.

In the mold and die industry, PSC End Mill Holders are used for creating intricate molds and dies with tight tolerances and high-quality surface finishes.

PSC End Mill Holders are widely used in general engineering and manufacturing for various machining operations, from prototyping to mass production.

Choosing the right PSC End Mill Holder is crucial for optimizing your machining operations. Here are some factors to consider:

Material: Select a holder made from high-quality materials for durability and performance.

Size: Ensure the holder is compatible with your machine and cutting tools.

Compatibility: Check the holder's compatibility with your specific machining requirements.

Precision: Look for holders with minimal runout for better accuracy.

Assess Your Machining Needs: Understand your specific machining requirements and choose a holder that meets those needs.

Consult with Experts: Seek advice from experienced professionals or tool manufacturers like Halnn for recommendations.

Overlooking Compatibility: Ensure the holder is compatible with your machine and cutting tools to avoid performance issues.

Ignoring Precision: Precision is crucial for high-quality machining, so avoid holders with high runout.

Proper maintenance is essential to extend the life of your PSC End Mill Holders and ensure consistent performance.

Regular Cleaning: Clean the holders regularly to remove debris and contaminants.

Proper Storage: Store holders in a clean, dry place to prevent corrosion and damage.

Use Proper Cleaning Tools: Use appropriate cleaning tools and solutions to avoid damaging the holders.

Organized Storage: Keep holders organized and easily accessible to prevent mishandling.

Tool Slippage: Ensure the collet and nut are tightened properly to prevent tool slippage.

Runout Issues: Regularly check for runout and replace worn components as needed.

Case Study 1: A leading aerospace manufacturer improved its machining precision and reduced tool wear by 30% after switching to Halnn's PSC End Mill Holders.

Case Study 2: An automotive parts supplier achieved a 20% increase in production efficiency and reduced tooling costs by using Halnn's PSC End Mill Holders.

Customer 1: "Halnn's PSC End Mill Holders have significantly improved our machining accuracy and efficiency. Their durability and performance are unmatched."

Customer 2: "Switching to Halnn's PSC End Mill Holders was a game-changer for our production line. We now achieve better surface finishes and longer tool life."

Halnn has over 18 years of experience in the precision tooling industry, providing high-quality solutions to various sectors. Our expertise ensures that we deliver reliable and innovative products.

At Halnn, we prioritize quality and customer satisfaction. Our rigorous quality control processes ensure that every PSC End Mill Holder meets the highest standards.

Halnn offers comprehensive technical support and after-sales service to assist customers with any issues or inquiries, ensuring a seamless experience.

PSC End Mill Holders are indispensable for achieving precision and efficiency in machining operations. Halnn, with its expertise and commitment to quality, offers top-of-the-line PSC End Mill Holders that cater to diverse industry needs. Whether you're in aerospace, automotive, medical device manufacturing, or general engineering, Halnn's PSC End Mill Holders provide the reliability and performance you need. Contact Halnn today to learn more about our products and how they can enhance your machining operations.

A: A PSC (Polygon Shank Coupling) End Mill Holder is a precision tool holder designed to securely hold end mills. It uses a polygonal shank design to ensure high stability and accuracy during machining operations.

A: PSC End Mill Holders offer enhanced precision, improved tool stability, reduced tool wear, and versatility. They provide a secure grip, minimize tool runout, and are suitable for various machining tasks.

A: The key difference lies in the polygonal shank design of PSC holders, which provides superior clamping force and precision compared to other designs. This results in better performance, especially in high-precision and high-speed machining operations.

A: PSC End Mill Holders are typically made from high-quality steel or other durable materials that ensure long-lasting performance and resistance to wear and tear.

A: While PSC End Mill Holders are versatile and compatible with many machines, it's essential to check the compatibility with your specific machine and tooling requirements. Halnn offers PSC End Mill Holders designed to fit a wide range of machines and applications.

A: Consider factors such as the size and material of the holder, the compatibility with your machine and end mills, and the precision requirements of your application. Consulting with experts or manufacturers like Halnn can also help you make an informed decision.

A: Regular cleaning to remove debris and contaminants, proper storage to prevent corrosion, and periodic checks for wear and runout are essential maintenance practices to ensure the longevity and performance of PSC End Mill Holders.

A: Halnn employs rigorous quality control processes, uses high-quality materials, and incorporates advanced engineering principles in the design and manufacturing of PSC End Mill Holders. Each product undergoes thorough testing to ensure it meets the highest standards of performance and reliability.

A: Yes, Halnn offers customization options to meet specific customer requirements. Whether you need a particular size or a unique design feature, Halnn can provide tailored solutions to enhance your machining operations.

A: Halnn's PSC End Mill Holders can be purchased directly from Halnn's official website, through authorized distributors, or by contacting Halnn's sales team for assistance.

A: PSC End Mill Holders are widely used in industries such as aerospace, automotive, medical device manufacturing, mold and die making, and general engineering due to their precision and versatility.

A: By providing a secure and stable grip, PSC End Mill Holders reduce tool wear and extend the life of cutting tools. This minimizes the need for frequent tool replacements, thereby lowering overall tooling costs.

For more information about PSC End Mill Holders and how Halnn can meet your machining needs, please visit our website or contact our customer support team.

Our website: https://www.halnncbn.com/

Email: halnntools@halnn-group.com

WhatsApp: +8615515925975

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.