In today's era of rapid technological development, the research and application of high-performance materials have become the key force to promote the progress of all walks of life. Aluminum-based silicon carbide, a new type of composite material, has become a new favorite in the fields of aviation, high-speed rail, and electronic packaging with its excellent physical and mechanical properties. In this context, Halnn's super-hard PCD inserts have become the key to solving this problem with their unparalleled performance.

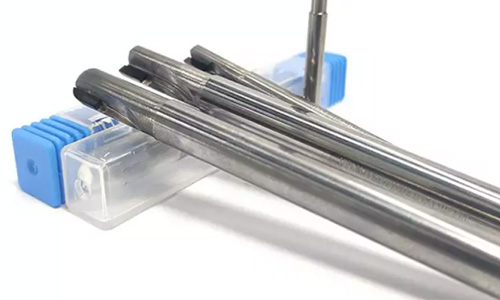

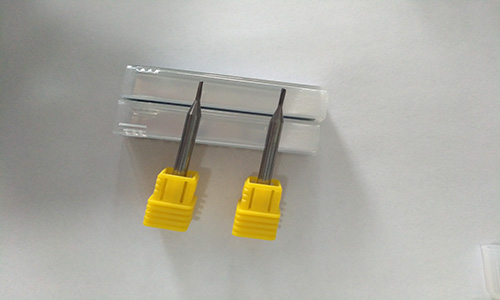

Drilling and milling are commonly used in the processing of aluminum-based silicon carbide parts. Halnn's PCD drills and PCD milling cutters use PCD cutting edges welded on the carbide tool matrix, which have ultra-high hardness and wear resistance. Commonly used PCD inserts include PCD end mills, PCD ball end mills, PCD drills, and diamond-coated milling cutters.

1. Halnn superhard PCD inserts have the characteristics of high hardness and high wear resistance. In the processing of aluminum-based silicon carbide, the tool material must have extraordinary hardness to effectively cope with the challenge of material hardness. Taking CDW010 material as an example, its hardness of up to 8000HV can easily cope with 2700HV aluminum-based silicon carbide processing, showing the advantage of PCD inserts in hardness.

2. Halnn superhard PCD inserts have high strength and toughness. In high-speed milling, Halnn superhard PCD inserts show better compressive strength than high-speed steel, cemented carbide and other inserts, making them more stable when subjected to cutting force and impact load, ensuring the continuity and safety of the processing process.

3. Halnn superhard PCD inserts have the characteristics of heat resistance and heat dissipation. The thermal conductivity of Halnn superhard CDW025 material PCD inserts is as high as 700W/mk, far exceeding cemented carbide, which can efficiently transfer cutting heat and reduce thermal damage to the tool. The low thermal expansion coefficient provides a reliable guarantee for its stability in high temperature environment.

4. Halnn superhard PCD inserts also have excellent processability and economy. This kind of artificial diamond tool is not only cost-effective, but also has strong plasticity. It can be made into inserts of various structural forms to meet different processing needs. Compared with carbide inserts, Halnn superhard PCD inserts have a longer service life, which brings obvious economic benefits to production.

In practical applications, Halnn superhard PCD inserts have been successfully used in high-speed milling, drilling and other processing processes of aluminum-based silicon carbide composites. By accurately controlling the cutting speed and cutting depth, Halnn superhard PCD inserts can optimize the surface quality of the workpiece while maintaining high cutting efficiency, ensuring high dimensional accuracy and surface finish of parts.

Below are the case parameters of CDW010 PCD milling cutter milling aluminum-based silicon carbide

Processing method: milling

Tool used: φ4 PCD end mill

Machine tool used: Beijing Precision Machinery

Processing part: step root cleaning

Application industry: satellite parts

Usage effect: The service life of a single cutting edge of the Halnn CDW010 material PCD milling cutter is 4 hours, which is 12 times the life of a carbide milling cutter and 1.5 times the life of a domestic brand PCD milling cutter.

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.