In today's industrial field, the quality and performance of cutting tools play a vital role in production efficiency and product quality. As a well-known company in the industry, Halnn has been committed to providing customers with high-quality cutting tool products. Among them, Halnn Rolls ring notching inserts has become the first choice of many companies with its excellent performance and reliable quality.

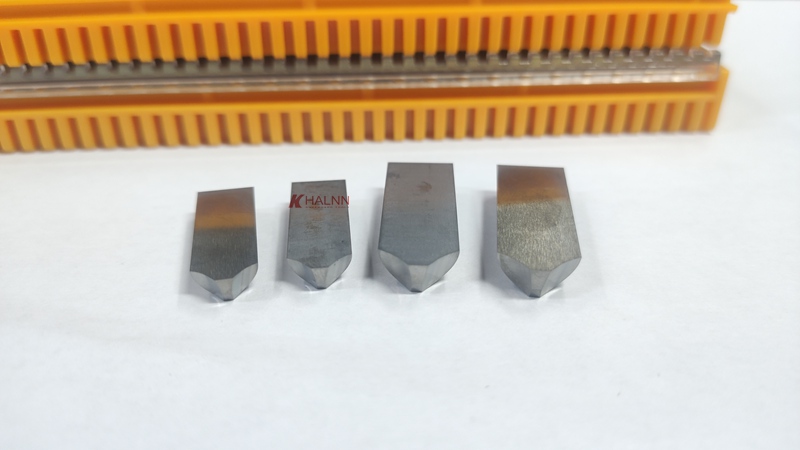

Halnn Rolls ring notching inserts is a tool specially designed by Halnn Company for processing carbide rolls. It uses advanced materials and manufacturing processes to ensure the high performance and long life of the tool. The material of Halnn Rolls ring notching inserts is mostly high-performance materials such as polycrystalline diamond. These materials have extremely high hardness and wear resistance, and can maintain good cutting performance when processing carbide rolls. At the same time, Halnn Company ensures that each Rolls ring notching inserts has stable performance and reliable quality through strict quality control and advanced production processes.

The hardness of Halnn Rolls ring notching inserts is as high as HV8000, which is far higher than that of traditional carbide tools. This makes it have higher cutting efficiency and longer service life when processing carbide rolls. According to statistics, the life of Halnn Rolls ring notching inserts is 20-30 times higher than that of carbide tools, saving a lot of tool replacement costs and time for enterprises.

Halnn Company adopts advanced grinding technology to ensure the dimensional accuracy consistency of Rolls ring notching insertss. This makes the tool have good controllability in various rotary engraving processes and can accurately process the required shape and size. At the same time, the friction coefficient of Halnn Rolls ring notching inserts is low, which reduces the heat generation during the processing process and improves the processing quality and tool life.

Halnn Rolls ring notching inserts is widely used in the processing of various carbide rolls and roller rings. Whether it is the crescent groove, the outer circle or the logo engraved in the outer circle groove, the Halnn roller ring engraving blade can easily cope with it, providing enterprises with efficient and accurate processing solutions.

In the high-speed steel roller engraving process and ring groove processing, the Halnn roller ring engraving blade also plays an important role. According to the different hardness of the roller, enterprises can choose different specifications of Halnn roller ring engraving blades to meet different processing needs.

As a professional tool manufacturer, Halnn Company has many years of industry experience and advanced technical strength. The company focuses on product research and development and innovation, and continuously launches new products that meet market demand. At the same time, Halnn Company also has a complete after-sales service system to provide customers with timely and professional technical support and services.

Halnn roller ring engraving blade has become an excellent choice in the field of industrial processing with its high hardness, long life, good processing controllability and other characteristics. Halnn Company will continue to uphold the business philosophy of "quality first, customer first" to provide customers with better quality tool products and services. I believe that with Halnn's efforts, Halnn's roller ring rib cutting blades will play a more important role in the industrial field and make greater contributions to promoting the development of the industry.

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.