In the world of roll machining, precision, efficiency, and durability are key to achieving high-quality results. Halnn, a leader in cutting tool technology, provides specialized Rolls CBN tools that meet the demanding requirements of various industries. Whether you’re working with hardened steel, cast iron, or high-alloy materials, Halnn Rolls CBN tools offer the reliability and performance necessary to ensure accuracy and longevity in your machining processes.

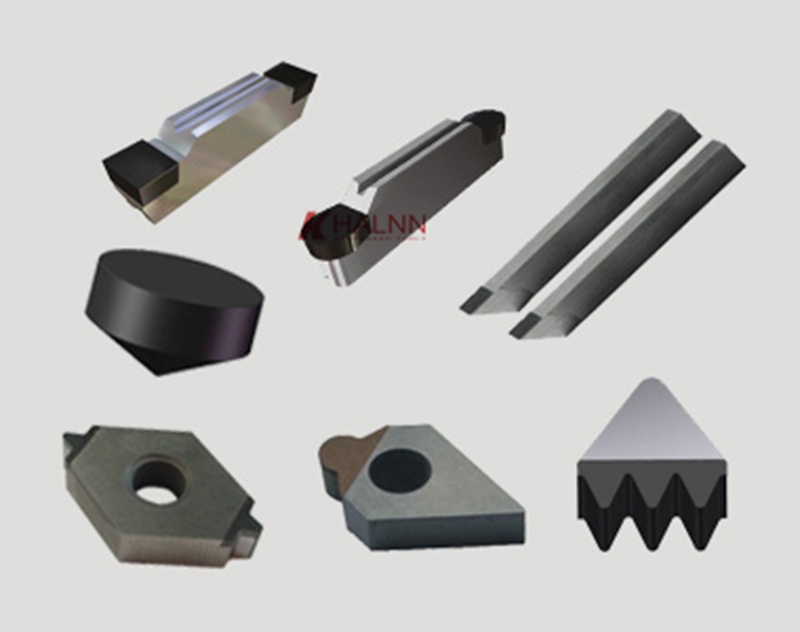

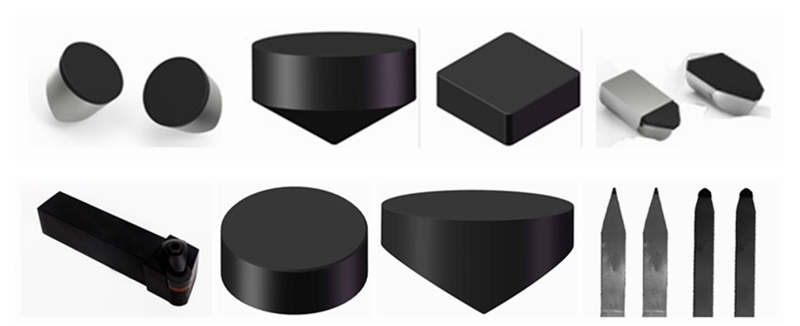

This article focuses on Rolls CBN tools, including Rolls CBN inserts, Rolls PCBN inserts, and Rolls PCBN tools, and highlights their features, benefits, and applications in rolls machining.

Rolls CBN tools are cutting tools specifically designed for machining rolls, which are typically used in industries like steel mills, metalworking, automotive, and aerospace. These tools are made from Cubic Boron Nitride (CBN), a super-hard material second only to diamond in hardness. This makes CBN ideal for machining tough materials that require high heat resistance, wear resistance, and long tool life.

In rolls machining, where the material hardness can be extremely high, Halnn Rolls CBN tools excel in providing consistent, precise results, even in the most challenging conditions.

Rolls are typically made from materials that are difficult to machine due to their hardness and wear resistance. Traditional cutting tools, such as carbide or ceramic, struggle to maintain sharpness and accuracy during continuous or interrupted cutting processes. Halnn Rolls CBN tools are specifically designed to overcome these challenges by offering:

Superior wear resistance, extending tool life.

Heat resistance, maintaining cutting performance at high speeds.

High hardness, ensuring precision and smooth surface finishes.

These properties make Rolls CBN tools an essential choice for manufacturers looking to achieve consistent, high-quality results.

Rolls CBN inserts are small, replaceable cutting edges used in turning, milling, and grooving operations. Halnn offers a wide range of Rolls CBN inserts, optimized for specific roll materials and machining conditions, providing users with tools that excel in both precision and durability.

Rolls PCBN inserts (Polycrystalline Cubic Boron Nitride) are even more wear-resistant than standard CBN inserts and are ideal for high-hardness materials like chilled cast iron and high-alloy steel rolls. Halnn Rolls PCBN inserts are engineered to deliver consistent performance during high-speed, high-volume machining.

Halnn Rolls PCBN tools are designed for specialized applications in rolls machining, offering unparalleled toughness, thermal stability, and sharpness retention. They are particularly effective in machining large rolls used in steel production, where material hardness and size pose significant challenges.

Halnn Rolls CBN tools offer superior hardness, making them ideal for machining rolls made from high-hardness materials. This hardness translates into high wear resistance, allowing for extended tool life and fewer tool changes.

Rolls machining often generates significant heat, especially during high-speed operations. Halnn CBN tools are designed to withstand these temperatures without compromising cutting performance, ensuring continuous production without overheating or tool degradation.

Halnn Rolls CBN tools are designed to provide precision in every cut, ensuring high surface quality. This is crucial in industries where smooth, accurate machining is essential to the final product's functionality and appearance.

Rolls often involve interrupted cutting due to grooves or patterns. Halnn Rolls CBN tools are engineered to handle these conditions without chipping or losing performance, ensuring longevity and reliability even in tough machining environments.

Halnn Rolls CBN tools last significantly longer than traditional cutting tools, thanks to their hardness and wear resistance. This extended tool life reduces downtime caused by tool changes and decreases overall tooling costs.

With longer-lasting tools and fewer interruptions, manufacturers can maintain high-speed machining without sacrificing quality. This boosts productivity and allows for faster production cycles, meeting the needs of high-demand industries.

While CBN tools may have a higher upfront cost than other tools, their longevity and reduced maintenance needs make them more cost-effective in the long run. Halnn Rolls CBN tools offer excellent value for companies focused on high-volume production.

With superior wear resistance and sharp cutting edges, Halnn Rolls CBN tools ensure consistent, accurate cuts. This results in better surface finishes and more precise roll dimensions, reducing the need for additional finishing processes.

In the automotive sector, rolls are used to produce engine blocks, brake discs, and other high-strength components. Halnn Rolls CBN tools offer the precision and durability needed to machine these materials efficiently.

The aerospace industry relies on rolls made from high-strength alloys like titanium and aluminum. Halnn Rolls PCBN tools are perfect for machining these materials with the necessary accuracy and surface finish quality.

Rolls used in steel mills are typically made from hardened materials like high-speed steel and chilled cast iron. Halnn Rolls CBN tools can handle these materials at high cutting speeds, reducing machining time while maintaining high-quality results.

For industries like heavy manufacturing, where large, high-hardness rolls are common, Halnn Rolls CBN tools provide unmatched durability and precision. They are ideal for applications that require high-volume, uninterrupted production.

Choosing the right CBN tool for your rolls machining operation depends on several factors:

Material: Consider the hardness and composition of the roll material to select the appropriate CBN grade.

Cutting Speed: Higher speeds may require more heat-resistant CBN tools.

Tool Geometry: Proper tool geometry ensures optimal cutting performance and surface finish.

Machining Conditions: Account for whether you are performing continuous or interrupted cutting to select the most durable tool.

Using the wrong CBN grade for the material.

Neglecting to factor in the thermal stability needed for high-speed operations.

Ignoring tool geometry and its impact on surface quality.

Rolls CBN tools are primarily used for machining rolls made from hard materials, such as cast iron, hardened steel, and other high-strength alloys. These tools are designed to handle the high hardness and wear resistance of rolls, making them ideal for industries like steel mills, automotive, aerospace, and metalworking.

CBN tools are known for their superior hardness and thermal stability, which allow them to machine high-hardness materials efficiently without wearing down quickly. Compared to carbide or ceramic tools, Rolls CBN tools provide a longer tool life, better surface finish, and the ability to work at high cutting speeds, reducing production costs and downtime.

Rolls CBN tools are suitable for machining a wide range of hard materials, including:

Hardened steel rolls

High-speed steel

Chilled cast iron

High-alloy rolls

These tools perform exceptionally well on materials with high hardness (above HRC 45), which are difficult to machine with traditional tools.

Rolls CBN tools typically last much longer than carbide or ceramic tools due to their exceptional wear resistance and ability to maintain sharpness even in high-heat conditions. This longer tool life results in fewer tool changes and reduced downtime, making them more cost-effective over time.

Yes, Rolls CBN tools are highly suitable for interrupted cutting operations, which are common in rolls machining. The high toughness of CBN allows it to withstand the mechanical shocks and vibrations associated with interrupted cuts, ensuring consistent performance without chipping or tool damage.

Yes, Rolls CBN tools can be used for both roughing and finishing operations. They offer high precision and a smooth surface finish, making them suitable for finishing tasks, while their wear resistance and durability also allow them to perform efficiently in roughing operations.

Choosing the right Rolls CBN tool depends on factors like:

Material hardness of the rolls

Cutting speed and feed rate

Type of cutting operation (continuous or interrupted)

Desired surface finish

Consulting with a Halnn representative can help you select the right CBN tool based on your specific machining conditions.

Rolls CBN tools are widely used in industries that require high-precision machining of hard materials. These industries include:

Steel mills

Automotive manufacturing (e.g., for engine components)

Aerospace (e.g., for high-strength alloys)

Heavy machinery and metalworking industries

Yes, Rolls CBN tools are capable of handling high-speed machining due to their excellent thermal stability. They maintain performance at high cutting speeds, allowing for faster production rates without compromising tool life or surface quality.

Halnn offers customized Rolls CBN tool solutions to meet specific machining requirements. Whether you need special tool geometries, coatings, or grades of CBN, Halnn can provide tailored tools that optimize performance for your unique production processes.

Halnn Rolls CBN tools offer the durability, precision, and reliability that modern manufacturing demands. Whether you're working in automotive, aerospace, steel mills, or heavy manufacturing, Halnn’s Rolls CBN inserts and Rolls PCBN tools provide superior performance, helping you achieve better machining results with fewer interruptions.

By choosing Halnn Rolls CBN tools, you invest in tools that last longer, perform better, and reduce overall production costs. Contact Halnn today to learn more about our comprehensive range of Rolls CBN tools and how we can support your specific machining needs.

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.