In the realm of precision machining and engine component manufacturing, PCD (Polycrystalline Diamond) grooving tools have revolutionized the industry. These tools are particularly vital for piston manufacturing, where accuracy and durability are paramount. >>

In the renewable energy sector, wind turbines play a crucial role in sustainable power generation. A key component ensuring the efficiency and reliability of these turbines is the gear system. >>

Piston groove tools are specialized machining instruments designed to create precise grooves in piston components. These grooves are crucial for housing piston rings, which are essential for maintaining the seal and proper functioning of internal combustion engines. >>

In the ever-evolving landscape of industrial machining, precision and durability are paramount. One of the standout innovations in this realm is the use of Piston PCD inserts. These cutting tools are essential for manufacturers aiming to enhance their machining processes, particularly in the automotive and aerospace industries. This article delves into the benefits and applications of Piston PCD inserts and Piston PCD tools, emphasizing their role in optimizing performance and cost-effectiveness. >>

PCD wheel hub insert is specially used for the external facing processing of aluminium alloy wheel hubs for cars. It is a high performance cutting tool and plays an important roles in automotive manufacturing industry and related fields. >>

High-speed steel, as a tool steel material with high hardness, high wear resistance and high compressive strength, occupies a pivotal position in the field of metal processing. It is widely used in manufacturing various cutting tools, molds and other high-strength tools. This article will deeply explore the features of Halnn CBN inserts for processing high-speed steel, and demonstrate its application effects in different scenarios through specific cases. >>

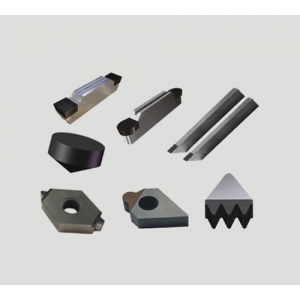

PCD (Polycrystalline Diamond) milling tools are a type of high-performance cutting tool used in various machining applications. They are designed for high-speed and high-precision milling operations, particularly in industries where materials are difficult to machine or require exceptionally fine finishes. Below is a detailed description of PCD milling tools, including their characteristics, uses, manufacturing processes, advantages, and best practices. >>

For wind turbine blade flange hole drilling, Halnn offers PCD fully laminated U drill inserts with excellent wear resistance, mainly W-shaped and S-shaped, which can be indexed 3-4 times to reduce production costs, and at the same time, it can withstand higher cutting speeds and feed speeds, combined with excellent rigidity of the tool holder, to achieve stable and efficient drilling while maintaining dimensional accuracy. >>

Due to the high hardness and good wear resistance, Halnn`s CBN inserts in heavy dutyTM series have become an ideal selection for supporting suppliers in fields such as rolling mills, wind power bearings, mining machinery, and heavy machinery. >>

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.