In the fast-paced world of gear manufacturing, efficiency and precision are paramount. Hobs with indexable carbide inserts have emerged as a groundbreaking solution, offering superior performance and cost-effectiveness. Halnn, a leader in cutting tool innovation, is at the forefront of this technological advancement. >>

In the realm of gear manufacturing, precision and efficiency are paramount. One tool that has revolutionized this field is the indexable gear milling cutter. This article delves into the intricacies of these advanced tools, their benefits, and their applications. >>

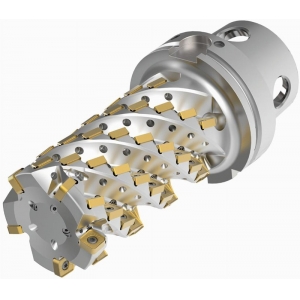

An indexable gear cutting tool is designed with replaceable inserts, allowing for continuous use and reduced downtime during maintenance. These tools are essential in various manufacturing processes, offering unparalleled precision and efficiency. Unlike traditional gear cutting tools, indexable gear cutting tools provide a flexible and cost-effective solution for producing high-quality gears. >>

Gear manufacturing is a cornerstone of modern industrial production, playing a vital role in various sectors, including automotive, aerospace, heavy machinery, and precision engineering. Among the tools used in this process, indexable gear rough milling cutters stand out for their efficiency and versatility. >>

In the demanding world of automotive and industrial manufacturing, precision and efficiency are paramount. Crankshaft machining, a critical process in engine production, requires specialized tools to meet these high standards. Halnn, a leader in cutting tool technology, offers advanced indexable crankshaft cutters designed to enhance performance and reliability. >>

Crankshaft cutting tools are essential components in the manufacturing of engine parts, playing a critical role in ensuring precision and efficiency. At Halnn, we specialize in providing high-quality crankshaft cutting tools designed to meet the rigorous demands of modern manufacturing. >>

Wind energy is a cornerstone of renewable energy strategies worldwide. The efficiency and performance of wind turbines are critically dependent on the quality and precision of their blades. Drilling is a vital process in the manufacturing and assembly of wind turbine blades, ensuring structural integrity and optimal performance. This article delves into the intricacies of wind turbine blade drilling, exploring advanced tools, techniques, and innovations. >>

In the realm of precision machining and engine component manufacturing, PCD (Polycrystalline Diamond) grooving tools have revolutionized the industry. These tools are particularly vital for piston manufacturing, where accuracy and durability are paramount. >>

In the renewable energy sector, wind turbines play a crucial role in sustainable power generation. A key component ensuring the efficiency and reliability of these turbines is the gear system. >>

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.