Most of parts in this field are made of hardened steel with HRC58-62. Therefore, BN-H series of full face PCBN inserts are specially designed.To address the different machining requirements, RNGN and CNGA PCBN inserts were recommended for gear end surface, inner bore and outer surface. >>

Investment in the wind power equipment manufacturing industry is high, but the machining of wind turbine bearing parts faces problems such as large size, weight, complex structure and precision maintenance. Halnn adopts innovative tool design and manufacturing technology, launches PCBN inserts series with high hardness and high wear resistance, launches PCBN inserts with special geometric designs for different parts, and provides non-standard customized products, which successfully improves cutting efficiency and machining quality and provides reliable solutions for the development of wind power industry. >>

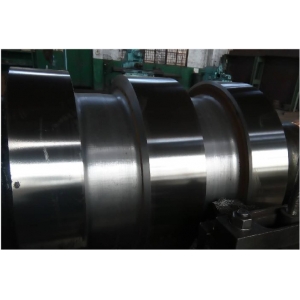

With the improvement of the rolling speed, the requirement for the hardness of mill roll is higher. Now, the main materials for rebar mill rolls are high speed steel and tungsten carbide. For the high-speed steel mill rolls,the notching tools and engraving tools of tungsten carbide are generally processed on the relevant CNC milling machine dedicated to the roll. They have required wear resistance and impact resistance for notching and engraving. For the grinding process of high-speed steel mill rolls, Halnn provides CBN grinding wheels to improve the efficiency. For the hardest tungsten carbide roller ring, we need to use CBN/PCD tools and CVD diamond tools to notch, engrave and grind such high-hardened materials. >>

carbide roll machining: carbide roll hardness HRC84.5-85, using Halnn CBN tools HLCBN isnerts, the tool life is 4 times higher than that of an imported CBN tools. >>

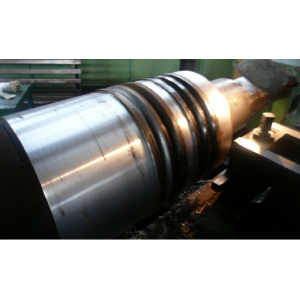

With the development of industrial automation, the metallurgical industry has increasing requirements for processing efficiency and quality. In this context, Halnn CBN inserts stand out. We will share the real case of a company specializing in the production of Chilled cast iron rolls. Previously, it took 30 hours to process a roll using carbide inserts, which was inefficient. However, by using Halnn CBN inserts and adjusting cutting parameters, they increased their efficiency by 5-10 times, from 30 hours to just 6 hours, creating amazing results. Halnn CBN inserts not only improve production efficiency, but also achieve surface quality improvement, bringing great satisfaction to customers. >>

In fact, as a large consumption part of the rolling mill, whether it is HSS rolls/High Boron Steel rolls/ cast iron rolls wire bar rolls, section rolls, narrow strip rolls, wear, crack or even spalling will inevitably occur in the production process. In the face of roll wear failure, production enterprises mostly use turning (CBN tools) or grinding to correct. Today, according to my own experience and turning cases, the author recommends several grades and choices of Halnn CBN tools commonly used in strip turning rolls, wire rod rolls turning and repair, profile rolls turning and repair. >>

This article will deeply discuss the tool structure, material characteristics and application cases of halnn diamond PCD tools in carbide roll ring machining. Through a comprehensive introduction to this tool, readers will better understand how halnn Diamond PCD tools can be used to optimize the carbide roll machining process, improve production efficiency and reduce production costs. Whether in steel production, metalworking or other fields,halnn Diamond PCD tools will be a trusted partner to help enterprises achieve more efficient and reliable roller and ring machining tasks. >>

With the progress of iron and steel rolling technology, the demand for wear resistance of the roll is higher and higher, which brings difficulties to the processing and repair of the roll. In particular, it has been a difficult problem to repair the HSS roll after use. Combined with the practical processing experience of roll repair in a large number of steel mills, Halnn has developed different CBN tool grades according to different roll repair conditions, which has successfully helped roll mills and steel mills at home and abroad to solve a series of similar problems. Compared with the ordinary carbide inserts, Halnn CBN inserts has a very obvious effect in machining the roll surface, which greatly improves the quality of the roll surface. Halnn CBN tool BN-S300 series repair high-speed steel pass roll turning case, the roll hardness reaches HRC63. After using Halnn CBN tool, the durability of the tool is increased to 60 minutes. There are Halnn CBN tools BN-S300 series repair pass rolls. After using Halnn CBN tools, the efficiency is 50% higher and the durability is 4 times higher than that of a well-known brand ceramic cutters. They clearly show the remarkable effect and effectiveness of Halnn CBN tools in repairing roll industry. >>

Halnn offers two choices of CBN inserts and PCD inserts for different types of rolls. CBN inserts, including BN-K1, BN-S20, BN-S200, BN-S300 and HLCBN, are recommended for High Boron Steel rolls and HSS rolls. For carbide rolls, Halnn recommends the use of PCD inserts, including full veneer PCD inserts RCGX models, PCD notching inserts and diamond engraving tools. Through these cases, the audience can be more at ease to choose halnn tools for roll machining. >>

For different roll materials, Halnn provides CBN tools and diamond PCD tools, such as high-hardness cast iron, cast steel, high-speed steel rolls. Halnn recommends CBN CNC inserts BN-K1, BN-S20, HLCBN and other materials. For the cemented carbide roll ring, generally according to the hardness distinction, for the hardness lower than HRA88 rough turning process, recommend CBN inserts suitable, for the hardness above HRA88 precision turning outer circle, chamfer, notching, marking and other processes, recommend the use of PCD tool, Halnn can provide a complete set of tools, such as PCD standard inserts, PCD notching inserts, diamond engraving tools. >>

The excellent use effect of Halnn CBN tools in the roll field stems from its excellent impact resistance and wear resistance. In the manufacturing process, Halnn pays attention to the selection of materials, the use of high-end equipment and the establishment of a strict inspection system to ensure the stability of product quality, which together promote Halnn CBN tools to achieve excellent results in the roll field. >>

In order to solve the problems of reverse rework, sand collapse and high surface hardness in the process of roll machining, Halnn specially developed a complete set of tool schemes, including turning, milling, grooving, notching, marking,etc., in addition to providing standard CBN tools/ diamond PCD inserts, Halnn also provides a series of products such as turning Arbor, milling Arbor, support block, CVD engraving tools, etc., to improve the machining efficiency of the roll. Matching of CBN tools/ diamond PCD tools materials and roll materials, perfect balance of tool wear resistance and impact toughness, appropriate machine tool cutting parameters and tool life, tool manufacturing standards and grinding standards. >>

For all inquiries, please fill in the form below (* are required) to send us a brief message, and we will get back to you as soon as possible.